The project Advanced Components for Industrial Digital Twins (a-CIDiT) starts. The kick-off meeting will be held on October 19/20 at Universidad de Valladolid.

The proposal is presented jointly by three institutions: Institute of Marine Research (IIM-CSIC), University of Burgos (UBU) and University of Valladolid (UVA), acting as coordinator, including also six external researchers, one from UPM in the research team, one from UPV in the work team, and the others from abroad.

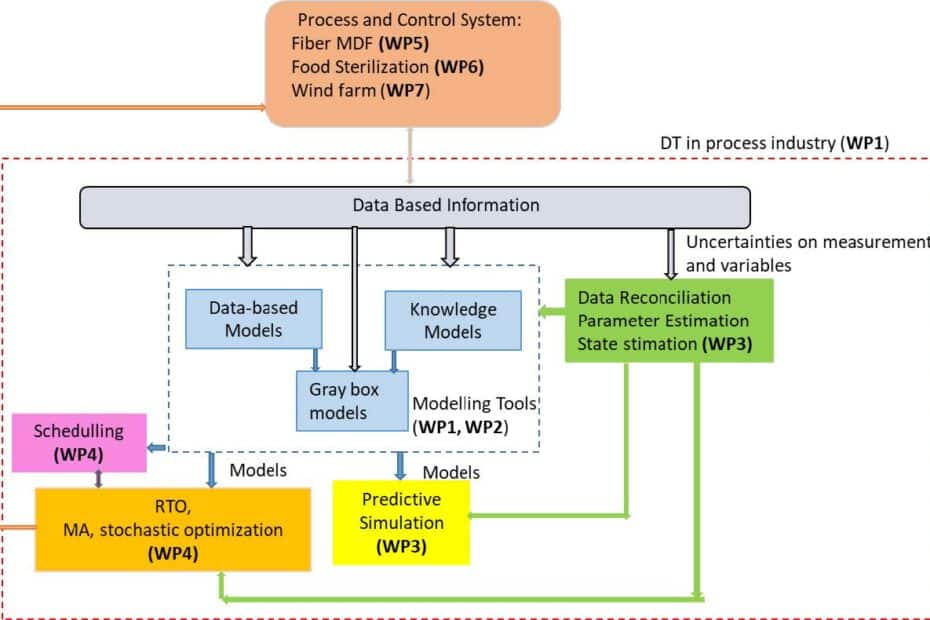

In the framework of the transformations introduced by the Industry 4.0 concept, and the consequent digitization of companies, the use of real-time data for analysis and decision-making is becoming extremely relevant. In this context, taking into account the complexity of the processes and the number of factors involved in rational decision-making, it is also necessary to rely on models and subsequent software tools. These advances in information management, together with the use of real-time models for decision-making have led to what is known as Digital Twins (DT).

In principle, a DT is a virtual representation of a physical entity. Here, virtual means software that usually includes mathematical models. Twin indicates that the software aims to mirror physical reality. In detail, there are many versions of what it is called DT but most of them contain at least:

- A database of operation data that allows monitoring and analysis in near real-time, usually with Artificial Intelligence (AI) tools.

- A process model continuously updated with plant data that is used for decision support with simulation and optimization techniques.

DT, seen as a technology to enable or facilitate decision-making support, can be applied to many different fields, each of them with different specificities and needs. DT are not independent entities, they must be connected and fed continuously with plant information in order to keep updated with the state of the monitored plant, and at the same time, must be conceived as an architecture that integrates different plug-in modules ready to be used with updated information

The project will be focused in achieving the general following objectives:

- Proposing a conceptual model/framework for DT building in industrial systems management

- Developing data-based modeling methods compatible with the system physics in order to build reliable grey-box models.

- Developing distributed parameter estimation and dynamic data reconciliation algorithms for large-scale dynamic models to be used in real time.

- Improving distributed simulation methods for large-scale systems, considering the integration of hybrid models (co-simulation).

- Developing distributed modifier adaptation algorithms to deal with structural plant-model mismatch in real-time optimization of large-scale systems.

- Proposing decomposition methods to efficiently address stochastic optimization in real time.

- Applying the developed advanced methods and technologies in the project case studies:

a. Medium density fibreboard manufacturing.

b. Food sterilization process.

c. Wind-turbine farms.

d. Laboratory resource-supply network of pilot plants.